4 Best Root Cause Analysis Methods for EHS Professionals

Root cause analysis is a technique for figuring out what caused a problem to happen. It’s a crucial skill for EHS managers, and we’ve highlighted four methods.

By Cory Sander

What does root cause analysis mean? It’s a technique for getting to the core of what caused a problem to happen in the first place. Let’s say you find a hazardous waste drum at your facility that’s supposed to have a lid on it but doesn’t. It’s a problem you easily fix by putting the lid back on, but if you walk away, you’ll likely come back two weeks later to the same issue.

The solution: root cause analysis. It’s a way to find out what caused the lid to be off in the first place, so you can correct the underlying problem. Does your new staff need training on hazardous waste? Was the lid poorly attached and fell off? Or was it something else entirely? As an EHS professional, you need to conduct a root cause analysis to find out, and we have four great methods to help you get started:

-

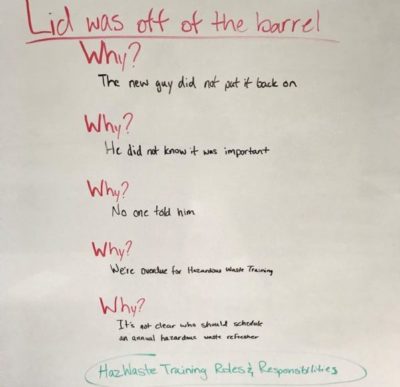

The 5 Whys

Conducting a five whys exercise is something you can easily do with your team. You simply ask the question “Why?” five times (or more) until you uncover the root cause of the problem. Why was the lid off the barrel? The new guy didn’t put it back on. Why? He didn’t know it was important. Why? No one told him. Why? We’re overdue for hazardous waste training. Why? It’s not clear who should schedule an annual hazardous waste refresher. Bingo. You have a roles and responsibilities problem around hazardous waste training. The root cause of the issue.

-

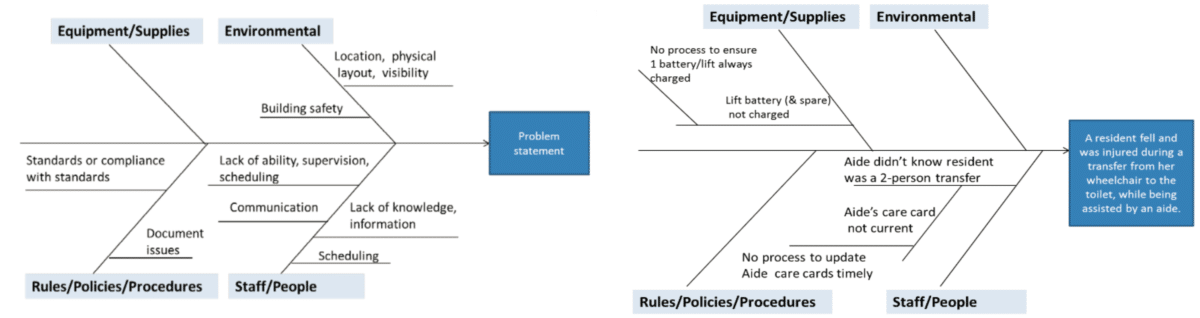

Fishbone Diagram

A fishbone or cause and effect diagram is just like it sounds. You draw a horizontal line on your whiteboard. Then slanted diagonal lines (the fish bones) on either side of it. Write your problem above the diagram and then label each fish bone as a category that might be related to your problem. These might be people, processes, documentation, and equipment. Then brainstorm causes related to each category and add them as additional lines coming off each fish bone. Finally, analyze your diagram to make a conclusion about the problem’s root cause.

-

Group Brainstorming

This is the most straightforward method for root cause analysis. You gather a group of people from your team—preferably those most likely to interact with that barrel—for a one-hour meeting. Let them know what you’re talking about ahead of time and make it clear that the point of the meeting is to find causes and solutions; not place blame. Appoint a meeting leader and a note taker then begin an open discussion around your problem. They key here is to create an environment where everyone feels safe and comfortable contributing to the conversation.

-

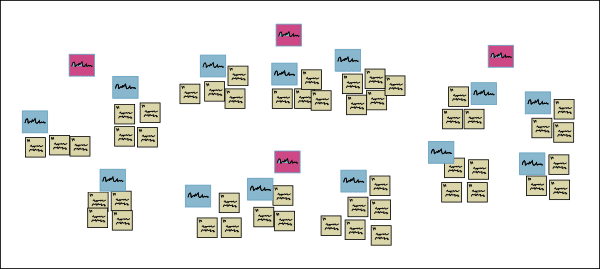

Affinity Diagramming

Try using this tool in conjunction with your brainstorming session. It’s a simple way to organize your results and recognize patterns. Let’s say your note taker from your brainstorm session records all the cause ideas from your session on individual post-it notes. Next, you’d stick them all on the wall and start organizing them under major themes. These might be training, safety, roles and responsibilities, and compliance. It’s a way to organize your thinking, recognize patterns and work toward a conclusion.

Identifying the root cause of a problem takes time and a solid methodology. But it pays off in the end when you don’t have to face the same problem over-and-over again. It’s also a good skill for your team to build, so you automatically start searching for root cause in the future.